Increase in production

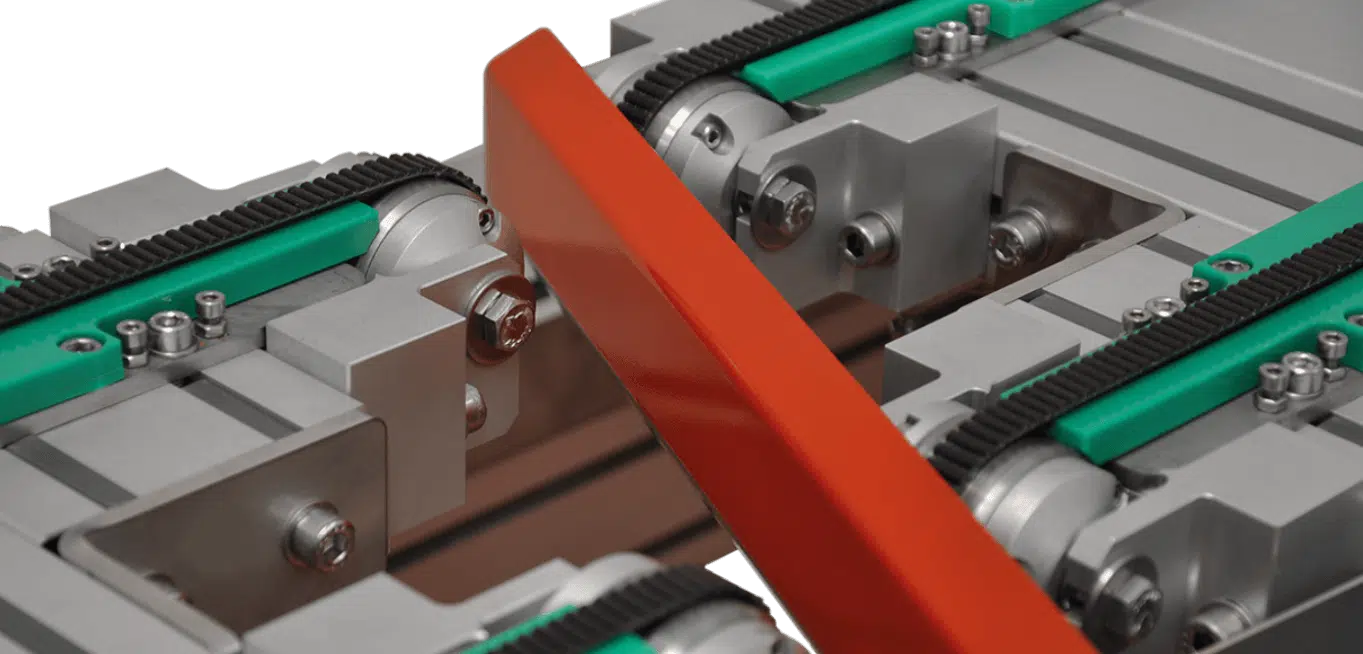

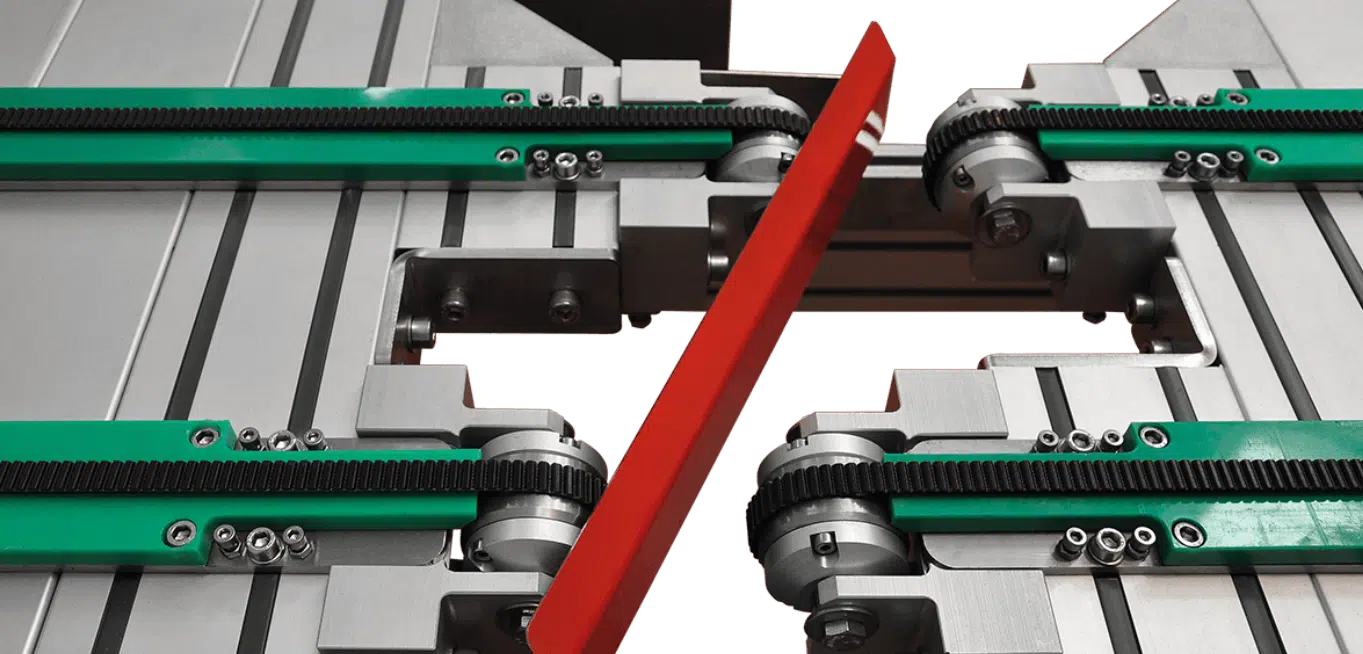

Cutting veil – inclined

The use of the veil cutter allows to reduce the waste of glaze, furthermore the rollers of the kiln remain clean as the tiles pass.

Description

The cutting veil machine is entirely made of stainless steel material and suitable for the 850 mm blade surface and the traditional bell system with a minimum size of 200×200 and a maximum of 660×660.

The machine is able to avoid the contact between the glaze and transport belts and consequently avoiding to smear the back side of tiles.

The use of the veil cutter allows to reduce the waste of glaze, furthermore the rollers of the kiln remain clean as the tiles pass; the result is therefore a lower maintenance service.

Inclined veil effect.

Benefits

Saving raw materials

Request Cutting veil – inclined information

Contact us directly for more detailed information on the machinery or for quotation requests, thank you.